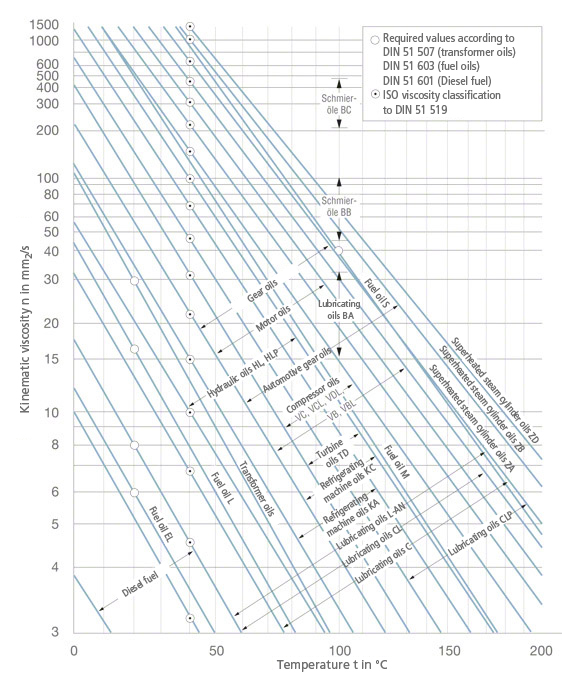

A fluid which is too viscous may prompt cavitation. Hydraulic components will operate efficiently only within a specific viscosity range, optimum operating range for each of them. As the viscosity decreases (when temperature increasing), the mechanical efficiency will increase due to low forces: As the temperature increases, liquid viscosity decreases and leakage becomes more significant, reducing the volumetric efficiency. Kinematic viscosity for some common liquids you can see at The Engineering ToolBox. NOTE: Equations above are for fluid with specific gravity 0.876 (like petroleum oil) and at fluids temperature 37.8☌ (100☏). For a quick and an approximate conversion you can use next formulas depends on viscosity range: SUS to cSt The conversion from Centistokes to Saybolt Universal Seconds in terms of calculations is specified by the ASTM D2161 and is not simple. In North America are more popular kinematic viscosity units Saybolt Universal Seconds (SUS) or Seconds Saybolt Universal (SSU). The SI unit for kinematic viscosity is m 2/s but the more common unit is the centistoke (cSt): The symbol for kinematic viscosity is the Greek letter nu (ν). The kinematic viscosity is the ratio of the dynamic viscosity μ to the density of the fluid ρ: It is easier to measure and more common to report the kinematic viscosity of a fluid.

The SI unit for dynamic viscosity is the pascal-second (Pa The symbol for dynamic viscosity is the Greek letter mu (µ). There are dynamic and kinematic viscosity are usually common for calculations. The viscosity is a measure of the fluid’s resistance to flow.

Si unit for kinematic viscosity iso#

Selecting the ISO VG (Viscosity Grade) for your system.Understanding the optimum operating viscosity range.Dynamic and kinematic viscosity in SI and British unit.

0 kommentar(er)

0 kommentar(er)